Performance Comparison Guide for Modern 3D Printing Systems

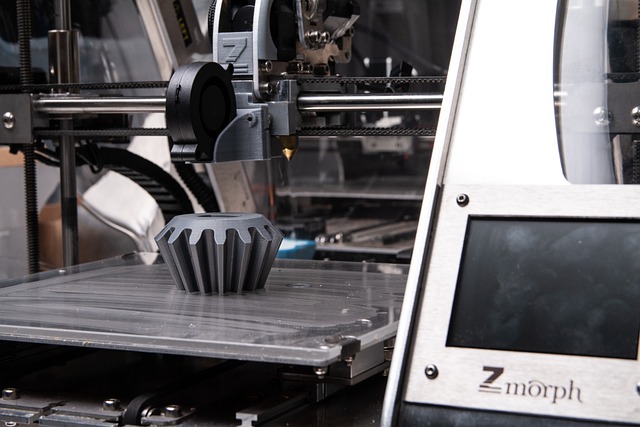

Modern 3D printing technology has evolved dramatically, offering unprecedented precision and versatility across multiple industries. From rapid prototyping to manufacturing complex components, today's 3D printers deliver remarkable capabilities that were unimaginable just a few years ago. Understanding the performance characteristics, features, and applications of different 3D printing systems is essential for making informed decisions whether you're a hobbyist, educator, or professional manufacturer.

The landscape of 3D printing continues to transform rapidly, with new technologies emerging that push the boundaries of what’s possible in additive manufacturing. Understanding the performance metrics and capabilities of modern 3D printing systems helps users select the right equipment for their specific needs and applications.

Exploring The Latest 3D Printing Technologies

The current generation of 3D printing technologies encompasses several distinct approaches, each with unique advantages. Fused Deposition Modeling (FDM) remains popular for its accessibility and material variety, while Stereolithography (SLA) offers superior surface finish and detail resolution. Selective Laser Sintering (SLS) provides exceptional strength for functional parts, and newer technologies like Multi Jet Fusion deliver production-scale capabilities with impressive speed and accuracy.

Each technology operates on different principles, affecting print quality, material compatibility, and overall performance. FDM printers heat thermoplastic filaments to create layers, making them ideal for prototyping and educational applications. SLA systems use liquid photopolymer resins cured by UV light, producing smooth surfaces perfect for detailed models and jewelry. SLS technology fuses powder materials using laser energy, creating durable parts without support structures.

Key Features To Consider When Choosing A 3D Printer

Selecting the right 3D printer requires careful evaluation of several critical features. Print volume determines the maximum size of objects you can create, while layer resolution affects surface quality and detail level. Build plate heating ensures proper adhesion for various materials, and enclosed chambers provide temperature stability for advanced filaments.

Connectivity options have become increasingly important, with wireless capabilities and cloud-based printing streamlining workflow management. Auto-leveling systems reduce setup time and improve print reliability, while filament detection sensors prevent failed prints due to material depletion. Software compatibility and user interface design significantly impact the overall printing experience, especially for beginners.

Advanced features like multi-material printing, automatic support generation, and print monitoring cameras add value but increase complexity and cost. Consider your skill level, intended applications, and available workspace when evaluating these features.

Understanding The Impact Of 3D Printing On Various Industries

3D printing has revolutionized manufacturing across numerous sectors, from aerospace and automotive to healthcare and education. In aerospace, companies use additive manufacturing to create lightweight components with complex geometries impossible through traditional methods. The automotive industry leverages 3D printing for rapid prototyping, custom tooling, and low-volume production parts.

Healthcare applications include custom prosthetics, surgical guides, and bioprinting research for tissue engineering. Educational institutions integrate 3D printing into curricula, enabling hands-on learning in engineering, design, and scientific concepts. Architecture firms create detailed scale models, while jewelry designers produce intricate pieces with unprecedented precision.

The technology’s impact extends to consumer goods, where companies use 3D printing for personalized products and on-demand manufacturing. This shift toward distributed production reduces inventory costs and enables mass customization previously economically unfeasible.

Expert Insights On 3D Printer Maintenance And Longevity

Proper maintenance significantly extends 3D printer lifespan and ensures consistent print quality. Regular cleaning of the print bed, nozzle, and build chamber prevents contamination and adhesion issues. Calibration checks should be performed periodically to maintain dimensional accuracy and layer adhesion.

Lubrication of moving parts prevents wear and reduces noise levels, while firmware updates often include performance improvements and new features. Proper storage of printing materials in dry, controlled environments prevents degradation that can affect print quality. Temperature and humidity monitoring in the printing environment helps maintain optimal conditions.

Replacement part availability and manufacturer support influence long-term ownership costs. Established brands typically offer better parts availability and technical support, while open-source designs provide flexibility for modifications and repairs.

Comparative Analysis Of 3D Printer Performance And User Reviews

Performance evaluation involves multiple metrics including print speed, accuracy, reliability, and ease of use. Print speed varies significantly between technologies and settings, with draft modes sacrificing quality for faster completion times. Accuracy depends on mechanical precision, software algorithms, and environmental factors like temperature stability.

User reviews consistently highlight the importance of reliable bed adhesion, consistent extrusion, and minimal print failures. Software quality significantly impacts user experience, with intuitive interfaces and robust slicing algorithms receiving positive feedback. Community support and available resources often determine long-term satisfaction, especially for users new to 3D printing.

| Printer Type | Technology | Price Range | Key Strengths |

|---|---|---|---|

| Entry-Level FDM | Fused Deposition Modeling | $200-$500 | Affordable, easy to use, wide material support |

| Professional FDM | Fused Deposition Modeling | $1,000-$5,000 | Large build volumes, enclosed chambers, reliability |

| Desktop SLA | Stereolithography | $300-$2,000 | High detail resolution, smooth surface finish |

| Industrial SLS | Selective Laser Sintering | $10,000-$50,000 | No support structures, strong functional parts |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

The 3D printing landscape continues evolving with new materials, improved reliability, and enhanced user experiences. Understanding performance characteristics across different technologies and price points enables informed decisions that align with specific requirements and budgets. Whether pursuing educational goals, professional applications, or creative projects, modern 3D printing systems offer unprecedented capabilities for bringing digital designs into physical reality.